Hi,

I need to attach a laser to a motoman mpl800 dx100.

The program is created with robodk software and will look something like this:

MOVJ C00000 VJ=100.0

MOVL C00001 V=150.0

CALL JOB:M3

MOVL C00002 V=150.0

MOVL C00003 V=4.00

MOVL C00004 V=4.00

MOVL C00005 V=4.00

MOVL C00006 V=150.0

CALL JOB:M9

MOVL C00007 V=150.0

CALL JOB:M3

The Call JOB:M3 needs to turn the laser on and the CALL JOB:M9 needs to turn it off.

The laser has a output wire with 5volt. The relay should then allow these 5 volts to go back to the laser through the input wire which will get it starting.

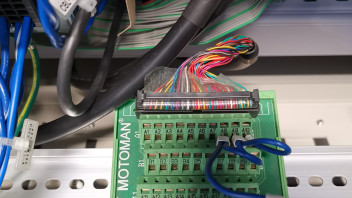

the cn307 connector looks like this

In which connector should the input wire and output wire go in the cn307? and is it correct to use the cn307?

So now I need to create the jobs M3 and M9 and somehow get them to turn the laser on/off.

From reading around the forum I guess I need a DOUT command but I don't know how the job should look or how I get it to point to right connector?

Any help will be highly appriciated as this is very new to me.