As far I can tell, Programming and Diagnosis Workspace pull just the contents of KRC folder (R1 and STEU subfolders).

Posts by massula

-

-

There is a product called ASCII Binary Translator, that can convert binary programs (prg format) to plain text (csr format), and is cheaper than full DTPS suite.

But it needs a license, so You should contact Your local Panasonic dealer to check the value and conditions.

-

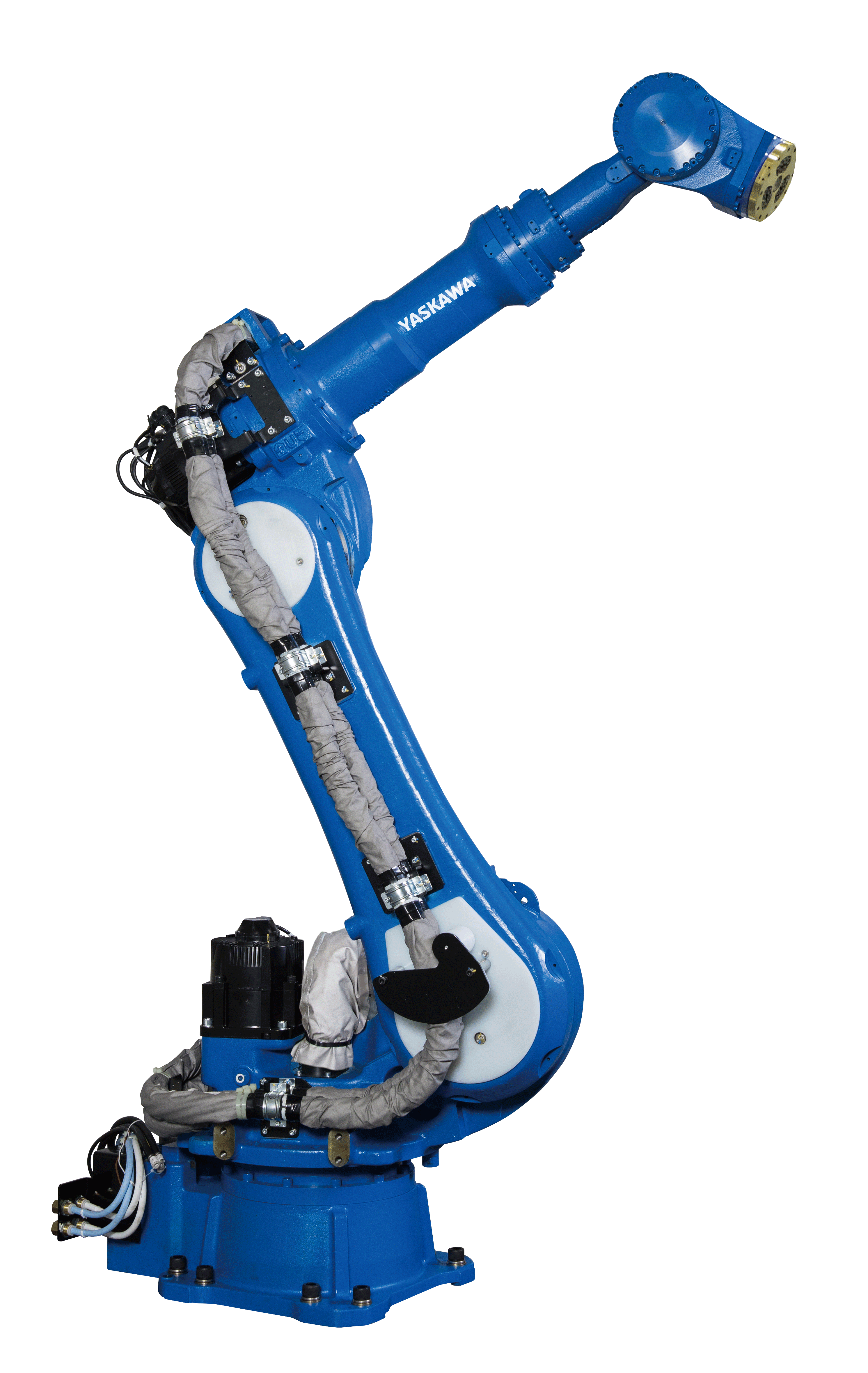

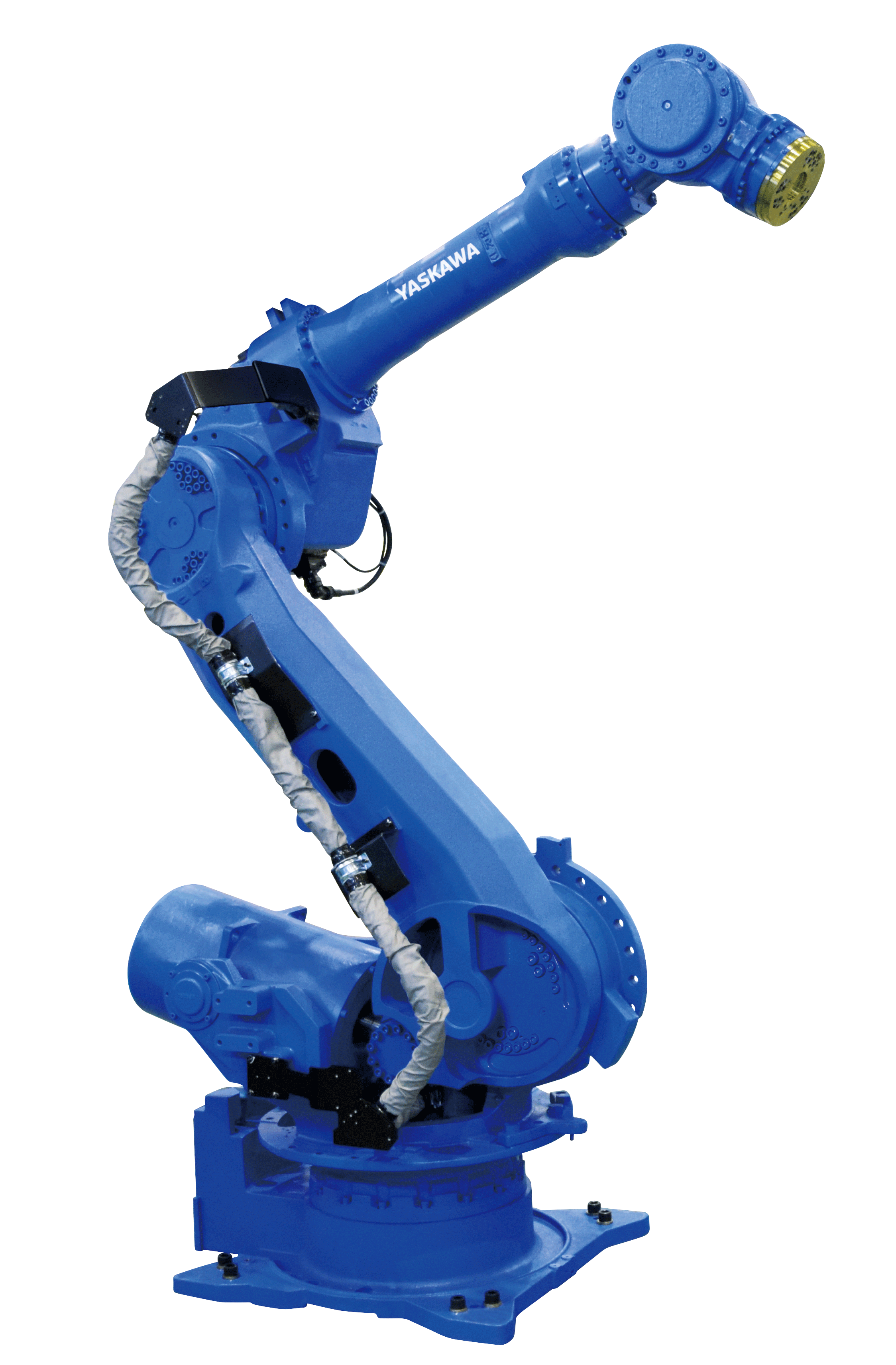

Different from other manufacturers, Yaskawa charges for the .cojts for their robots models.

If You don't want to pay, You can go to their website, download their 3D cad files for these specific models (links below) and make the .cojts by Yourself.

GP110

GP250

-

I'm not sure if You will find what You are searching on this site but, anyway, here follows the link:

Developer PortalResources for developers and robot programmers building solutions around Yaskawa Motoman robotics productsdeveloper.motoman.comIt asks for a login with a Github account to when You want to download something.

-

Good to know. Thanks for the info!

-

Why Motosim ? if they all need to be purchased, Job Editor seems more straightforward to me, as it basically open a JBI file. But I actually never tried them, so I might be misleading.

I would also recommend MotoSim.

As fas I can tell, Job Editor is still being offered by Yaskawa, but its not being updated anymore. And for Job Editor You would need a different license for each controller model. So now You would need Job Editor for FS100. But if in the future Your company acquire a YRC1000, for example, You would need another license, and so on.

MotoSim, on the other hand require just one license for any controller from NX100 to YRC1000micro. So You will be covered on future needs.

Also MotoSim (and I'm referring to the EG-VRC version) has JobPad, that is a stripped version of Job Editor.

-

So, does Yaskawa has a syntax-checker or anything else that would help building a syntax error free file ?

Or, if You have the time and the skills, write your own Python/Powershell/Whaterver-language scripts to check some common errors (blank lines , spaces where they should't need to be, etc). And, when You pick new errors, You can include them on Your tool. The advantage of this approach that this script would be taylor-made to Your needs.

And these scripts could be used in conjunction with any smart text editor (Notepad++, UltraEdit, VS Code, etc).

But You need to consider if this would worth the time.

-

Yaskawa has MotoSim and Job Editor.

There is also third party Dramat DRES, that is introducing some Yaskawa functions on its latest releases.

-

II want make program changes offline and the reload back into the robot, without ASCII Uploader. What am I not doing?

You can't.

At least You can't edit .tp files with a regular text editor.

.tp files must be changed on Roboguide or on robot itself.

-

What options, exactly?

-

I just purchased Robotstudio and i think it's 2023 version. I have been trying to watch the tutorial on ABB website, but they have different options than I do so it's impossible to follow along.

Please look at the image attached. The big picture is on my computer, the small one is ABB tutorial. One option is when he tells me to use the tech instruction, it is greyed out, plus I don't even have some of the options like freehand like they do.

Also, when i login the software says I need Robotware, but when I try and download a version of robotware i get an unspecified error. I am dreading learning this software, but I have to do it. My boss is giving me 4 hours a day to learn it so I can help techs with the real robots. Thanks in advance.

Looking at the images You posted, Your RobotStudio is too old, 2019.x or probably 6.0x series.

If Yes, Add-ins tab will not work anymore, and You need to find the RobotWare You want and install it manually, and depending on the version of RobotWare You are trying to install, it won't work, either.

To see what is Your version, got to File > Help menus.

Mine is 2023, and its complaining about a new version around.

-

So, first things first: has your controller the Karel option installed?

You didn't mentioned Your controller model and, in these cases, details matter. Judging by the mechanical arm model, I'm guessing that is a R-30iA controller, with software 7.something, and here is the trick: if I recall correctly, from R-30iA and onward, Karel stopped being a standard option and became a paid option.

3.1)

To check Your user available memory, go to MENU > Next > Status > Memory, and look for TPP memory.

You must have something like this.

In this case, I have almost 1 MB of free storage. There are some methods to expand this memory, but don't expect to much.

3.2)

You can check this on to MENU > Next > Status > Version ID > CONFIG, scroll down the list an look for KAREL (R632) option. If your controller don't have Karel, You will need some workaround.

3.3)

I wouldn't recommend pull programs from network, at least right now. This will add an extra layer of complexity on You project. Try to pull the programs from an external storage device physically attached to Your robot controller, as a USB stick or, better, a compact flash card.

You should note that, if You follow this route, You need to take care of some aspects, for example, if You change a program on teach pendant, You need to write this program on the storage device again, or create some method to synchronize it.

And, about Karel programming itself, You can try to search forum. I'm not sure, but I think I saw some Karel snippets here and there that make this load>run>delete scheme.

-

Is Your robot controller a KRC2 or a VKRC2? There are differences in their safety circuits.

Based on the pictures You posted, I'm guessing that is a KRC2, but I'm not 100% sure.

-

HP3L is an old robot.

Depending on the method used to split the step file, You can really have robot moving to wrong places. Where this step came from?

If You have a RoboDK valid license, You can ask them to build the robot for You. They can make this. -

So, I think You need to divide this project on smaller steps

1) Generate code on proper robot language

2) Upload the program to the robot

3) Check if this particular robot memory would accept Your programs.

1) You already answered about the lack of a TP languagr post processor on Your NX installation, so You would need to create a Python script to handle this. Another approach would use a "man in the middle" software, like RoboDK, for example. If NX generate paths on G-Code, You could import it on RoboDK and after export it to a .LS file. But a Pyython script is a good idea as well. You would need to take care of the syntax, but since You have acess to a real robot and Roboguide, You can also can make some reverse engineering, creating programs in these platforms, looking at headers and other sections of the files and adapting Your Python scripts as needed.

2) You need to check if Your robot has

Ascii Program Loader R796

Ascii Upload R507

Software options installed

Take a look here:

PostRe: ASCII UPLOAD OPTION / KAREL PROGRAMMING VS TRADITION .TP

Hi, rcran2015

TP files are binary files used by controller, normally for user programming. Unless you have a FANUC specific tool, You can't open them in a regular text editor.

LS files are a human readable format understood by FANUC controllers, and TP files can be exported as LS files. You cand read and edit LS files using a normal text editor.

Normally, you can export your TP files as LS through MENU > FILE > File > [BACKUP] > ASCII programs

But, the fact You can export to LS files doesnt mean… massula

massulaNovember 15, 2016 at 4:37 PM If Yes, You are covered. If not, You would need to upload the .LS files to Roboguide, and download this programs in the .TP native format..

3) You need to check the TPP memory available on Your robot controller. Newer the controller, bigger the memory. Anyway, milling and printing programs tend to be huge, so in case of You can't upload everything to the robot, You need to "slice" Your programs on smaller parts and load and delete them according to some events. The poor man option would require some karel and/or .cm scripts pulling files from an external storage device (and the knowledge to make it). The other option would involve commercial available software. I believe FANUC has something like this, and other companies offer similar solutions as well.

-

how can you export to MD? Mine said it`s protected

You need to export FROM MD: (read MD: contents)

Not TO MD: (write on MD:)

-

I'm not 100% sure, but I believe NX has post-processors to some robot manufacturers, including FANUC, so in theory You could have a program exported directly in FANUC TP language.

What You must look is if this post-processors require additional licenses.

Another attention point is if Your robot has ASCII upload option, to load .LS files directly. If not, You would first need to convert the .LS files to .TP files, the format FANUC controllers understand by default.

And You also need to take care of programs size. If the programs are too big and robot refuses to load it because of its memory limitations, You need to find a way to "stream" the programs to robot memory.

-

There was an old program from ABB (then ASEA, if I recall correctly) called just OLP, what could open and edit robot programs (in ARLA language, at that time).

If by any chance someone here has some OLP docs in electronic format (manuals, brochures, etc) and can share it with me, I would be very happy.

-

Did You followed these instructions?

-

Hello,

Is there any possible way to connect k-roset with tia portal (S70-PLCSIM Advanced or real PLC). I want to make virtual commissioning and i just wonder how to test plc program with robots.I dont't know if is possible to connect K-Roset directly on PLC Sim or a real PLC.

On simulators from other brands, sometimes people use bridges through OPC UA, but this would require some effort to make it work.

Another option would be using an agnostic tool, as Process Simulate or DELMIA, that have these features ready, but requires separated licenses.