The Project Goal

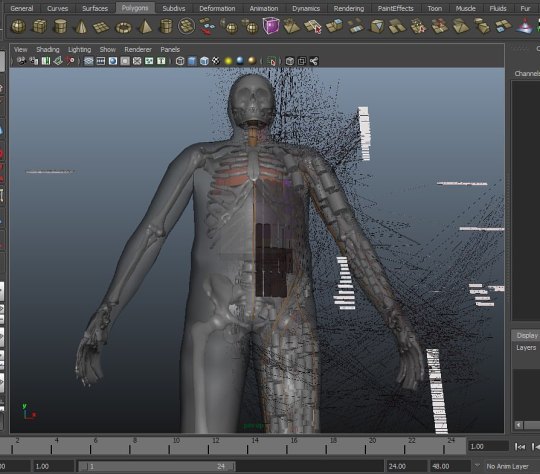

I'm planning to build an advanced humanoid robot. Think Ex Machina, The Terminator, Data from Star Trek, etc... So just like Data on Star Trek's creator created Data to look just like him, I'm making mine a mirror image of myself! I want the robot to ultimately move like a human, be able to walk, run, jump, do chores, dance, do sports, have conversations realistically, paint, do sculpture, etc. Hope you enjoy following me on my EPIC journey ![]()

About Me

I'm Larry. I have a background in computer programming as well as a lot of trades (electrical, mechanical, construction, etc). I also am an artist - sculptor, painter. I consider myself an inventor and an innovator. My current inspiration is Elon Musk.

Robot Features Planned

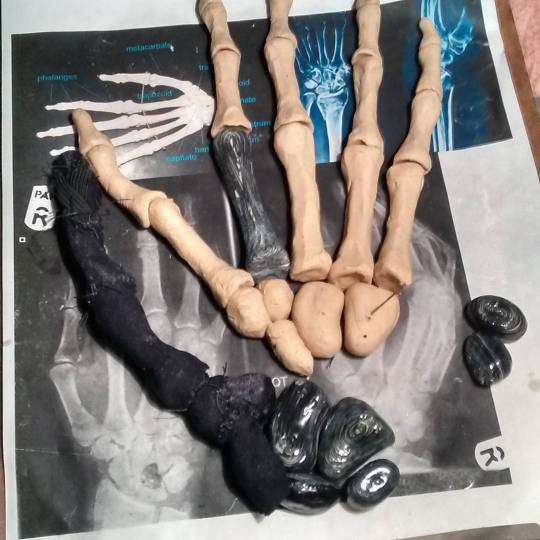

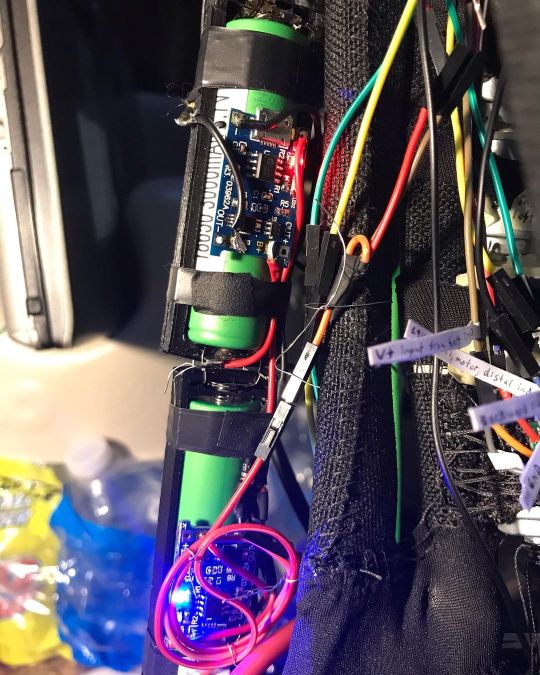

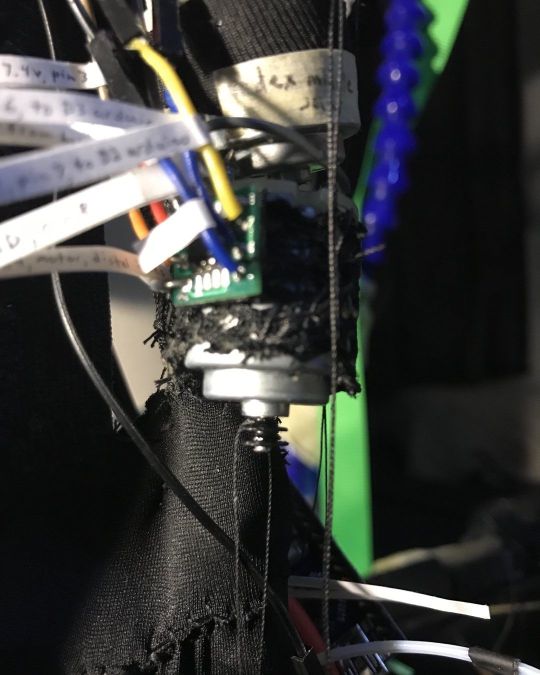

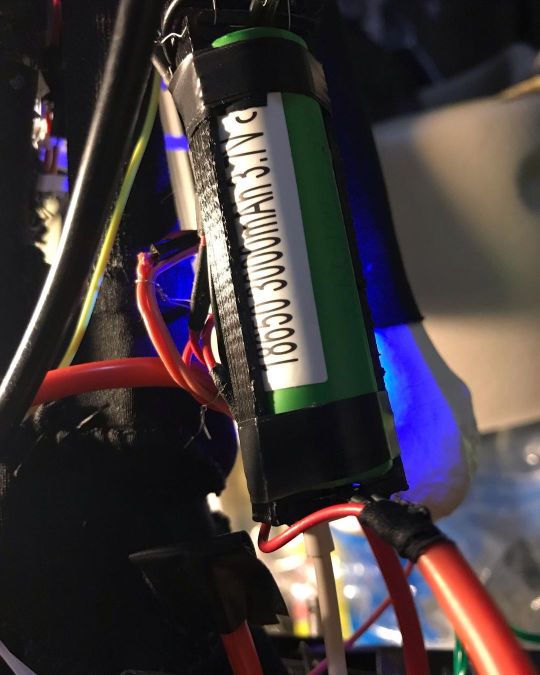

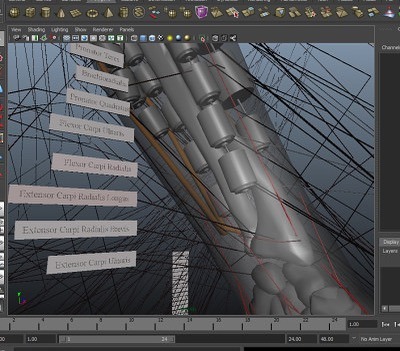

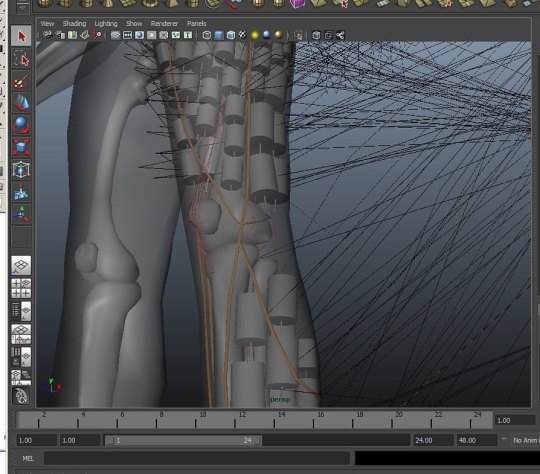

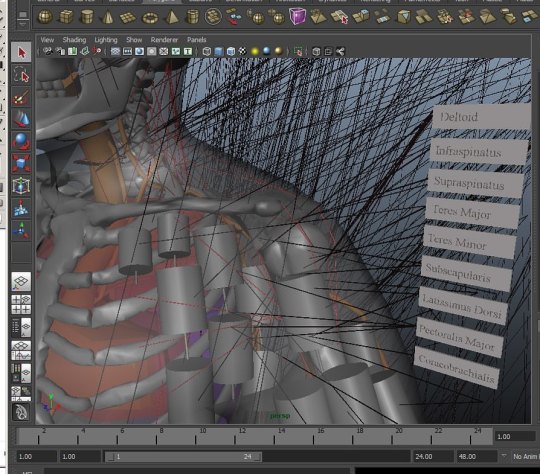

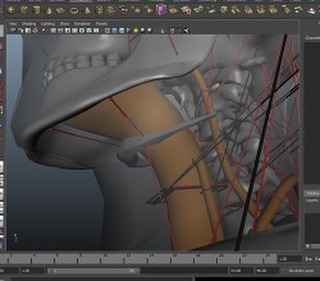

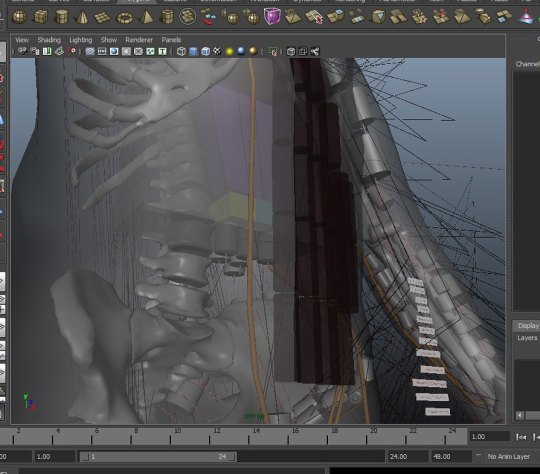

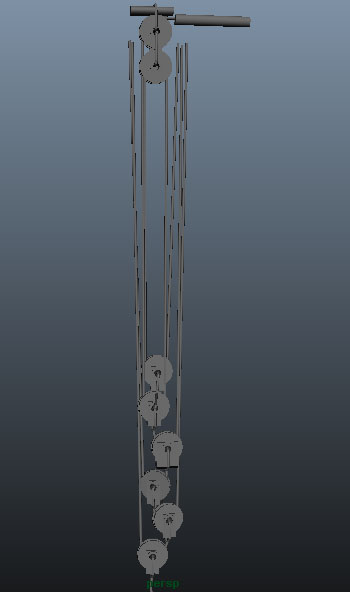

I plan to start out sculpting the left arm and hand, rigging them up with servo motors, connecting that up to a pc, and getting it to grasp. From there I will develop the torso, the scull, the legs, the feet, and the other arm. The bot will have silicone skin and look realistic and move realistic. It will have artificial lungs for cooling. It will have spandex ligaments and pulley systems to imitate muscles. It will have sensors to feel if it bumps into things and it will have webcam eyes. It will have a speaker in the mouth to speak with and the mouth will move to lipsync what it is saying. It will have facial expressions. It will have advanced artificial intelligence. It will run on battery and/or power cable depending on the situation.

I am interested in feedback, suggestions, advice, etc from everyone as I go. I find it quite helpful. I also enjoy sharing what I learn as a way to give back.

http://www.artbyrobot.com

https://www.facebook.com/artbyrobot

https://www.patreon.com/artbyrobot

https://www.twitch.tv/artbyrobot

http://www.twitter.com/artbyrobot

https://instagram.com/artbyrobot

https://www.youtube.com/c/artbyrobot1