Hello all,

I have some IRB-2600-20/1.65 robots. The have mounted flat grippers that are picking bags with products. Everything is intalled by the integrator and working well. But for my learning and to know where is the border of product weight or eg. if I can instal additional actuator on gripper I would like to know how to calculate if max load and torque is OK or not for the robot. OFC it's good to kno about it before starting the production, making additioan gripper etc. etc. So I need to know theory (also I'm relatively fresh in working with industrial robots).

Problem is that i founded some formulas for calculation in ABB documentation But if I use it it looks that robot should never to be able to work well with products that's running from beginning without any problems. I suppose that my calculation are wrong

So I hope that here is someone who will find the time to check it ![]()

What I found in documentation - Product specification irb 2600 (page 47) for Ax5 is:

Ja5 = Load x ((Z + 0,0852 + L2) + max (J0x, J0y) ≤ 2.0 kgm2

for Ax6

Ja6 = Load x L2 + J0Z ≤ 1.0 kgm2

I' m not sure if I should use it, but i didn't found anything more

Some what's my way of thinking:

Input data:

Exactly, by products I mean group of products hold together by griper (it can be eg. 3 bags like on drawing or 2 etc.) I've putted dimension and weight for whole package

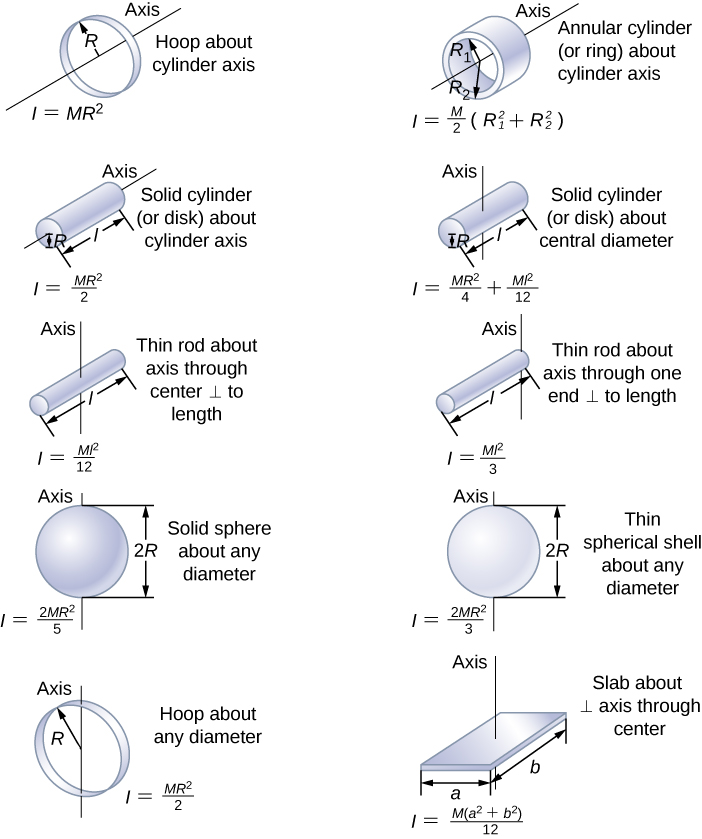

Then I've calculated moment of intertia for gripper and products. Product and gripper has cuboid shape

And now we have moment where I'm not so sure

Data from below substitiuted to formula

The have written that L=sqr(x2 + y2).

As you see the target (Ja 5 ≤ 2.0 kgm2 and ja6 ≤ 1.0 kgm2) is unfuillfuiled

First question is if you should use this formula? And if yes, what's wrong? ![]()

thanks