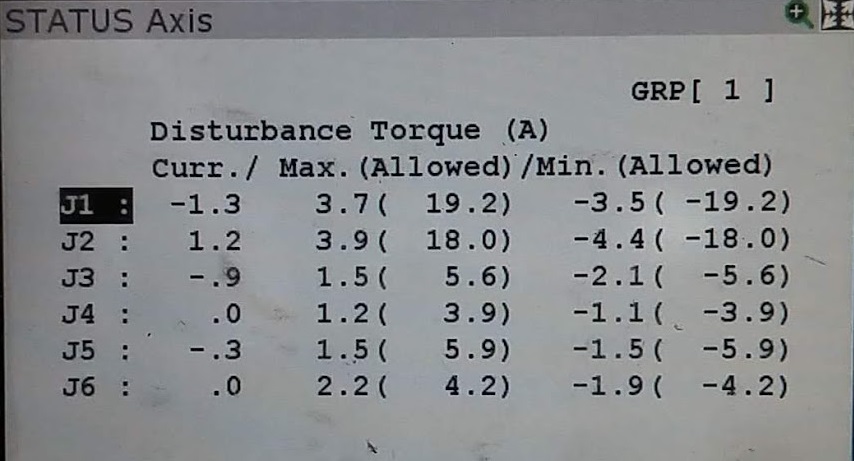

Guys - I sometimes get collision detect error on my Fanuc robot

I always check the joint values after getting this to make sure all joint are within my axis limits

And they always are, none of my joints are at extreme or close to extreme

My weld wire is also not touching anything , its far away from the clamp or part or surface

My collision sensitivity is 60%

Is there anyother reason for this ????